Back to workshop stories

1970 350 Coupe Body Off and Repaint

-

2nd Apr 04

The chassis on Graemes car was very rotten in the usual places. Had this been the only issues then it wouldn't have been so bad but there were also a lot of body issues and a rotten windshield frame to boot.

-

-

20th Apr 04

The laborious and unpleasant task of stripping the many layers of paint. This started to uncover some real horror stories.

-

-

1st Jul 04

And this is what we were all waiting for...The specially built 350 cubic inch 430hp small block motor, complete with aluminium heads and serpentine pulley system.

-

-

4th Sep 04

The original windscreen frame upper rail removed and the replacement piece let in.

-

-

5th Sep 04

There was extensive damage to the right hand rear wing, here a new one is bonded into place.

-

-

25th Nov 04

The engine hooked up to the T56 6 speed transmission. at the time there were no off the shelf kits for this conversion so it all had to be figured out. You can see transmission mount needs to be moved further back.

-

-

26th Nov 04

Whilst all this was going on we set about repairing some more of the bodywork. Here the right hand inner fender has been removed for repair.

-

-

4th Feb 05

With the body back on temporarily, we modified a 700R4 crossmember to take the transmission and this worked well for us. We had to figure out how to get the shifter lever through the factory console next.

-

-

3rd Jun 05

Once the transmission mounts and linkages were figured out the body was removed for the last time so everything could be cleaned and painted. Looking good!

-

-

4th Jun 05

A close up shot of the shifter and transmission mount, we used a Hurst shifter lever and made our own end for it to bolt to the shifter. The final picture shows the differences between a stock crossmember and our modified tubular assembly.

-

-

5th Jun 05

A close up of the Steeroids rack and pinion steering.

-

-

6th Jun 05

And the rebuilt rear suspension showing the Smart Struts, rebuilt trailing arms and driveshafts

-

-

7th Jun 05

This shows the transmission/bell housing adapter plate and the Ceramic coated headers. I have never been a fan of headers but Graeme insisted on this one....

This also shows the hi-torque reduction gear starter, smaller and more powerful than stock. -

-

18th Jun 05

The engine bay after its final coats of satin black, the wiring looms have been cleaned and repaired where necessary and a new wiper motor installed. You can see here the MSD ignition control box installed under the fender.

The final picture shows the Hydroboost power brake conversion, this works off the power steering and is perfect for cars that have a very aggressive cam and don't make good vacuum at idle. -

-

19th Jun 05

And then it was back to bodywork, we spent a lot of time on the headlight fit and they looked superb by the time we were done. The shifter was finished so the hole size could be finalised and tidied up and a retainer made for the shifter boot, the notches in the fibreglass around the tunnel are for J-nuts.

-

-

18th Jul 05

By now the bodywork is finished. There was a lot of work here. We wound up replacing the RH rear fender, the tail light panel and rear valence, the bonnet, and a door.

The high rise bonnet was a terrible fit and took a good deal of work to make it fit well, but our perseverance paid off and by the end of it all the panel fit was superb.GM never got the doors to fit like that baby! -

-

13th Aug 05

Here is the car in primer and blocked, just about ready for topcoat.

-

-

17th Aug 05

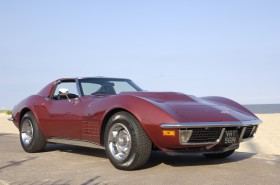

And this is what it is all for, fresh in Marlboro Maroon and looking awesome.

-

-

12th Sep 05

So begins the slow process of fitting all the trim, starting to take shape now!

Thats my buddies old 71 keeping it company. -

-

16th Sep 05

When it was all over Graeme flew down to give the car a couple of days good shakedown to iron out any snags before the long trip back to Scotland, he looks pretty happy!

-

-

19th Sep 05

Part of the shakedown was a photoshoot with Mike Key for American Car World magazine.

What a car! It looked absolutely stunning and drove superbly. This one got the best of everything and is just a fabulous machine in every respect. Besides the crate engine and transmission, flawless body and paint, theres also the aluminium radiator and electric cooling fans, hydroboost system, rack and pinion steering, smart struts, and so on. Some Corvettes are just lucky I guess! -